Niehoff @ wire China 2018

Niehoff at wire China 2018

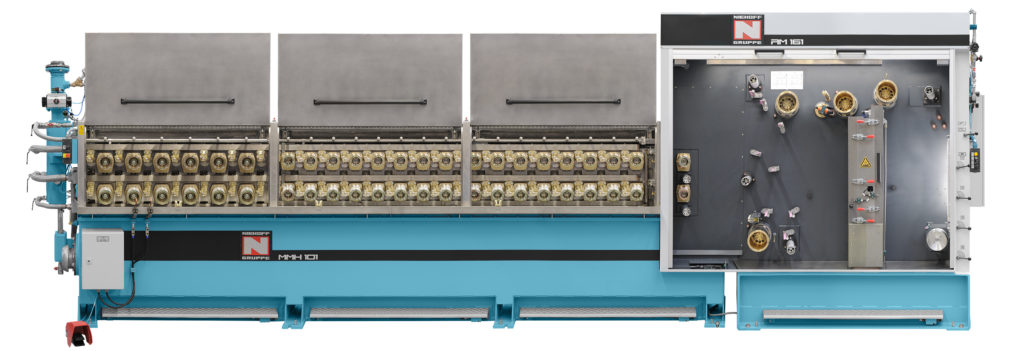

Maschinenfabrik Niehoff and Niehoff Machinery Changzhou Co., Ltd. (NMC), Niehoff’s Chinese subsidiary, will display at the wire China 2018 trade fair, booth W1F63, an MMH 101 + RM 161 type multiwire drawing line from Germany, as well as a high speed double twist bunching machine type D 631.5 and an NPS SV 400 D type double spooler, both built by NMC.

The booth was increased by 100 m² to 250 m² which shows that the wire China trade fair has become the second most important trade fair for Niehoff after the wire Düsseldorf. H. Folke Sandelin AB (HFSAB), specialized in horizontal lead extrusion and cable repair and recovery systems, will be as a sub-exhibitor at the booth.

The multiwire drawing line MMH 101 + RM 161 type continuous resistance annealer is designed to draw simultaneously 20 copper wires in 23 drafts from 1.8 mm diameter to a minimum final diameter of 0.16 … 0.50 mm.

The exhibits

The multiwire drawing machine MMH 101 combined with an RM 161 type continuous resistance annealer is designed to draw simultaneously 20 copper wires in 23 drafts from 1.8 mm diameter to a minimum final diameter of 0.16 … 0.50 mm.

The MMH range of multiwire drawing machines are designed for copper and aluminium wires and based on a modular principle. Therefore, these machines can be built ideally adapted to the specific tasks of customers.

The wires drawn on MMH type machines exceed the most demanding specifications and processing requirements and can be processed to multiwire bundles with outstanding characteristics. Up to now, more than 1,500 MMH lines are in operation world-wide.

The D 631.5 single-bow double twist bunching machine combined with an ARH 630 tangential pay-off, built by NMC under Niehoff license, is designed for strands with a cross section of 0.09 to 6.00 mm² and a steplessly variable lay length of 6 to 100 mm. The maximum number of twists is 6,500 twists/min while the maximum linear speed is 300 m/min.

The machine is equipped with sensor technology corresponding to the requirements of Industry 4.0 capability and enabling measurement of the preset lay length, motor and drive data, speed, and meter lengths.

Further features are AC drive technology, contactless transmission of machine data within the machine, field proven energy-saving ECO-Bow and an NMI touch-screen display with color user interface and simplified navigation structure. Another special feature is the perfect tension control for the winding of the strand from beginning to the end of bobbin using a load cell and dancer.

The SV 400 D type double spooler, part of the NPS cable handling system, for a long time tried and tested in practice,

is designed to operate in-line with extrusion lines and can spool insulated wires with a cross section of 0.22 … 6.0 mm² and an outer diameter of 1.0 … 5.0 mm (including insulation). The machine is capable of accommodating all NPS 400 multiway spools with a traverse width of 100 to 400 mm and can be operated at a maximum speed of 1500 m/min. Spool change is carried out automatically. By means of sensor technology according to Industry 4.0 and with the Niehoff Digital Assistant+ 4.0, machine, production and process data can be recorded. Thus continuous process monitoring and machine condition analysis are possible.

The NPS consists of the SV type spoolers and the collapsible NPS plastic multiway spools. The wire laying technology offers a secure, stable and tangle-free package on the NPS spools both when full or partially empty enabling highest cable pay-off speeds into downstream processes. Empty NPS spools can be dismantled, require less return shipping space than traditional spools, can be easily re-assembled and re-used.

Niehoff in China

Maschinenfabrik Niehoff has been active in China since the early 1970s. Assisted by experienced Chinese engineers, Niehoff has successfully introduced rod breakdown and multiwire as well as super fine wire drawing technology to many wire and cable factories in China. One of the pillars on which this success in the marketplace is built was the Niehoff Service Center in Shanghai founded in 1994 which became the Niehoff Shanghai Representative Office in 2000. Later changed to the Shanghai Sales Branch of Niehoff Machinery Changzhou (NMC) Co., Ltd. NMC, a subsidiary of the Niehoff Group which was founded in 2011. NMC operates a factory with modern production equipment and manufactures different kind of wire and cable machines under Niehoff license for the Chinese market and is also responsible for the complete after-sales service and the reliable and fast supply of Niehoff’s Chinese customers with Niehoff Original+ parts for all Niehoff machinery. NMC is situated in the Wujin Economic Development Zone in Changzhou, approximately 200 km west of Shanghai.

Complete solutions from a single source

Maschinenfabrik Niehoff develops and builds with an experience of more than 60 years all machinery – with the exception of extruders – needed for the production and the downstream processing of non-ferrous wires into automotive, power, data and special cables. In addition, the portfolio contains technical assistance by professional specialists who speak the customers´ languages. The reliable supply with original Niehoff wear parts and spare parts, machinery inspection, refurbishment and maintenance measures as well as machine operator and maintenance training courses complete the range of services. Niehoff Group offers custom-tailored solutions from development and planning to turnkey projects of complete cable factories.

The Group with nearly 800 employees worldwide is comprised of its headquarters, five manufacturing subsidiaries (in Brazil, the US, the Czech Republic, India, and China) as well as sales and service centers in Japan, Singapore and Russia.

Source: WIRE AND TUBE NEWS