Salzgitter Hydrogen —— Entry into renewable H2 production for CO2-low steel produnction

© Salzgitter AG

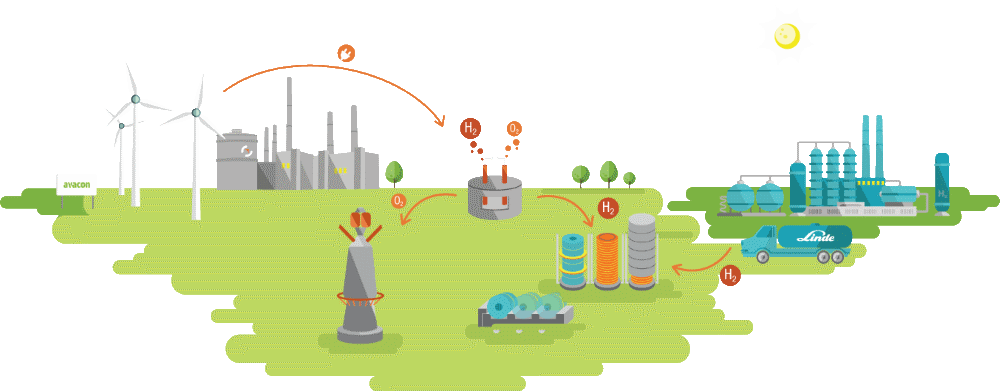

The aim of the “Salzgitter Hydrogen” sector-interconnection project is to generate hydrogen in Salzgitter through electrolysis and electricity from wind power. These activities are intended to put down the foundation for harnessing larger volumes of hydrogen in the future to reduce direct CO2 emissions in the production of steel.

Avacon plans to build and operate seven wind turbines with an output of 30 megawatts on the premises of the Salzgitter Group, three of which will be located on the grounds of the steel mill. Industrial gas supplier Linde will ensure the steady supply of hydrogen. Within the context of this project, the partners are aiming to build up know-how for the environmentally compatible production of hydrogen, as well as for gaining experience with the on-site production of hydrogen and its incorporation into an integrated steel mill with its complex production processes.

Hydrogen delivered by Linde is already used today in the annealing processes that are part of producing steel. In addition, the use of hydrogen in mills opens up potential for significantly reducing the CO2 emissions generated from steel production processes in the future.

With a view to achieving this goal, Salzgitter AG conceived the SALCOS® (Salzgitter Low CO2 Steelmaking) project that maps a realistic path toward the gradual reduction of CO2 and, in the long term, steel production that is virtually free of CO2. As part of this project, hydrogen generated from renewable energies is to replace the carbon so far required for the smelting of iron ore.

Salzgitter Flachstahl is endeavoring to gain operational experience through this project in the area of generating “hydrogen from renewable energies” that is so important for SALCOS®. Subsequently, this experience could be drawn on for the implementation on an industrial scale.

Although the framework conditions prevailing today do not permit the commercial operation of a direct combination of wind energy generation and electrolysis operations without government funding, the three partners are determined to develop and advance this technology that is so significant for the future and for climate protection.

© Salzgitter AG

Avacon plans to build and operate seven wind turbines with an output of 30 megawatts on the premises of the Salzgitter Group, three of which will be located on the grounds of the steel mill. From then on, these plants will supply the Salzgitter location with green electricity and ensure that Salzgitter AG can operate in a fully environmentally compatible manner in the future.

Salzgitter Flachstahl is planning the construction and operation of a PEM (PEM = Proton-Exchange Membrane) electrolysis plant with a capacity of around 400 Nm³/h. Avacon plans to build and operate seven wind turbines with an output of 30 megawatts on the premises of the Salzgitter Group. Three wind turbines will be located on the grounds of the steel mill.

Industrial gas supplier Linde will ensure the reliable, ongoing supply of hydrogen. The cost of the entire project (installation of the wind turbines and the hydrogen plant, including linking them up to the existing distribution networks) amounts to around € 50 million. Subsidies are also needed to finance this ground breaking industrial climate protection project. Assuming the project runs smoothly, the production of hydrogen on the plant premises could commence in 2020.