Borouge and Borealis confirmed to participate in wire China 2020

Borouge is a leading petrochemicals company that provides innovative plastics solutions for the energy, infrastructure, mobility, packaging, healthcare and agriculture industries. Established in 1998, Borouge is a joint venture between ADNOC and Borealis.

Borealis is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers. With its head office in Vienna, Austria, the company currently has around 6,900 employees and operates in over 120 countries. Borealis generated EUR 8,1 billion in sales revenue and a net profit of EUR 872 million in 2019.

Borealis and Borouge have joined hands to attend wire China for several editions, providing high quality products and service to global clients, and aiming to proactively benefit society by taking on real societal challenges and offering real solutions. Both companies will continue to showcase the state-of-the-art products and technology innovations at wire China 2020. They are committed to the principles of Responsible Care®, an initiative to improve safety performance within the chemical industry, and work to solve the world's water and sanitation challenges through product innovation and their Water for the World programme.

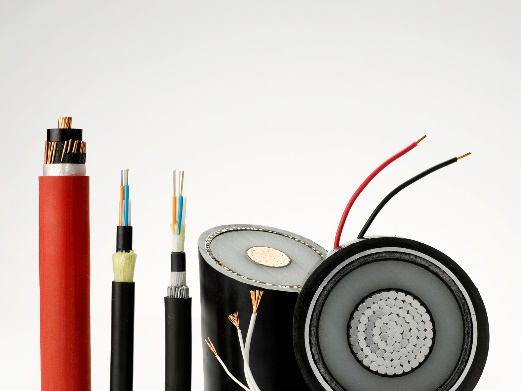

Product profile:

Borlink™ XLPE insulation for MV/HV/EHV/HVDC

Borlink™ XLPE insulation compounds for high voltage applications. These compounds are produced in contamination free environments, and packed under clean room conditions in octabins. Consequently, Borlink™ insulation compounds provide:

•The highest level of cleanliness

•A reduced risk of degradation by contaminants

•A consistent performance and long-term reliability

The cleanliness of Borlink™ compounds helps cable manufacturers in a number of ways:

•Better scorch safety

•Longer intervals between cleaning - longer production runs

•Lower degassing burden

•10-20% shorter production cycles

Borstar® PE jacket compounds

Borstar® jacketing compounds have been specifically developed for energy and telecommunication cables. Although the properties of cable jackets can vary among applications, all Borstar® PE jacketing compounds allow for:

•Highly efficient cable production

o Superior processability

o Consistent quality

•Easier cable installations

o Excellent abrasion and scratch resistance

o Outstanding surface hardness

•Long cable lifetime

o Reduced shrinkage

o Excellent environmental stress cracking resistance (ESCR)

o UV resistant

o Low water permeability

o Resistance to heat deformation and termites

Visico™/Ambicat™ LV XLPE

Because our Visico™ based material is reactor-made, the quality is high and extremely consistent. Our high-productivity solutions are based on our proprietary Visico™/Ambicat™ambient moisture cure, silane crosslinked polyethylene (XLPE) technology. Tangible benefits to our customers include:

•Increased production efficiency of high-quality, moisture cure LV cables thanks to reduced production complexity and less scrap produced

•Higher production output of cable using existing equipment

•Faster production cycles requiring less manpower

•Production campaigns of up to several weeks due to unique scorch retardant solution

•Crosslinking under ambient conditions without the need for elevated temperatures (elimination of water bath or sauna saves energy)

•Low environmental impact: catalyst system has no tin and contains neither flammable liquids nor harmful additives

wire China 2020 will take place on 23-26 September at Shanghai New International Expo Center. Visit Borealis and Borouge booth at W1F01.